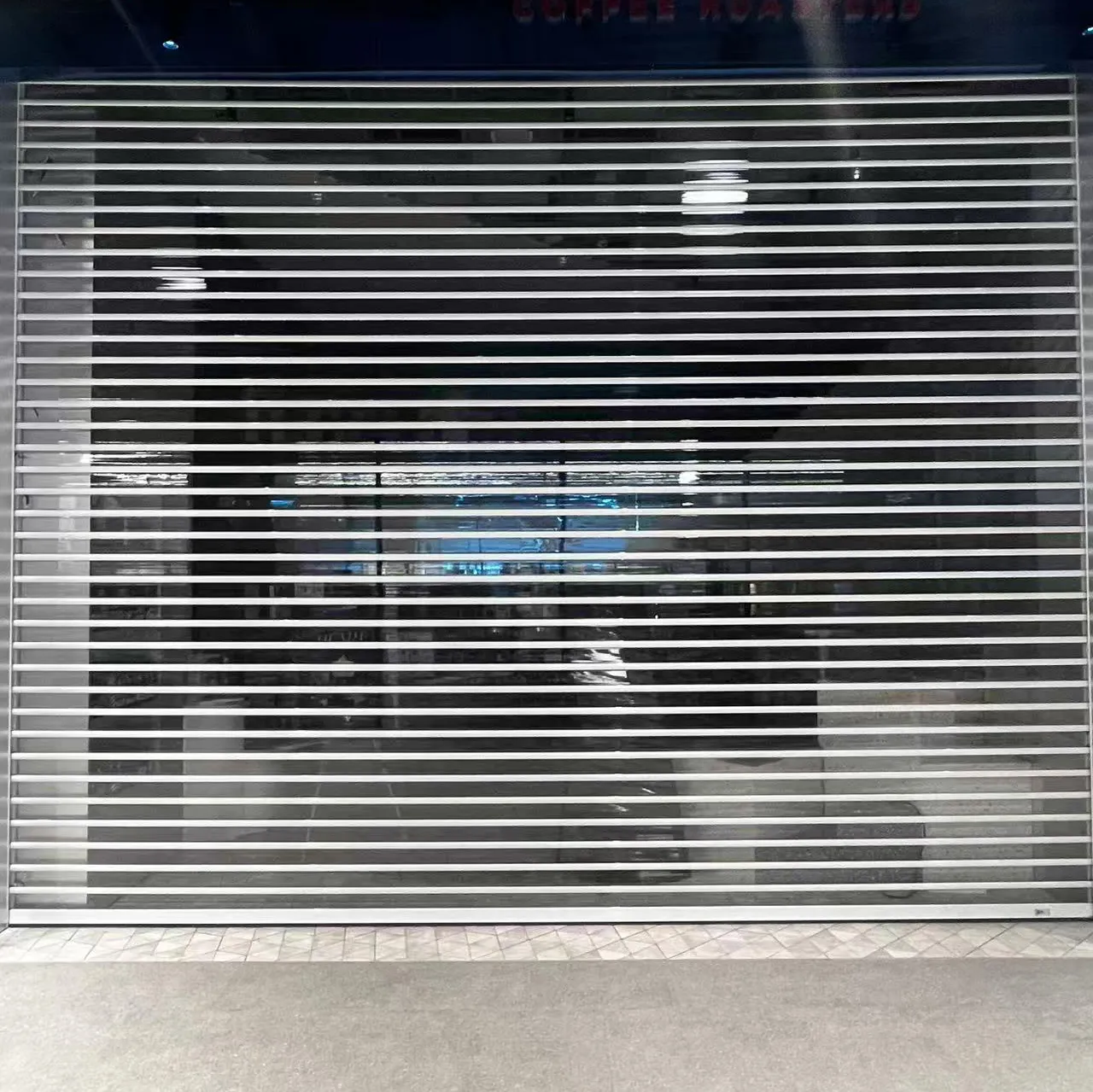

Crystal Rolling Shutter Door: Transparent Guard and Fashion Choice for Modern Business

In modern business environments and architectural designs, traditional rolling shutter doors are widely popular for their durability. However, with the increase in aesthetic needs and functional expectations, a new type of rolling shutter door that integrates beauty, safety and transparency - crystal rolling shutter doors, with its unique charm, are quickly becoming the new favorite of commercial stores, high-end exhibition halls, shopping malls and even some residential garages that pay attention to style.

First, the material is revealed: the excellent performance of polycarbonate

The core charm of crystal rolling shutter doors is derived from its main constituent material - high-quality polycarbonate (Polycarbonate, referred to as PC). Polycarbonate is a thermoplastic engineering plastic with excellent comprehensive properties, known as "transparent steel" or "bulletproof glue". Its characteristics give crystal rolling shutter doors many unparalleled advantages:

Ultra-high transparency: The door sheet of crystal rolling shutter doors is precision-processed from transparent polycarbonate plates, and its light transmittance can be as high as 85-90%. The visual effect is as clear and translucent as crystal, and it can almost achieve a display effect comparable to glass. This makes even after the store is closed, the goods displayed inside are still clearly visible, achieving a 24-hour "window advertising" effect. Excellent impact strength: Unlike glass that seems transparent but fragile, the impact strength of polycarbonate is 200-250 times that of ordinary glass and several times or even dozens of times that of tempered glass. This means that the crystal rolling shutter door can effectively resist external impact, is not easy to break, greatly improves safety, and can effectively prevent malicious damage and illegal intrusion. Lightweight and high strength: Compared with traditional metal rolling shutter doors, polycarbonate is lighter, which not only makes the door opening and closing more labor-saving (whether manual or electric), but also reduces the load-bearing pressure on the building structure. At the same time, its high strength characteristics ensure the durability and stability of the door. Excellent weather resistance and anti-aging: The surface of high-quality polycarbonate sheet is usually treated with UV (ultraviolet) coating, which can effectively resist the erosion of ultraviolet rays, prevent the door sheet from yellowing, aging and brittle cracking due to long-term sun exposure, and maintain long-term beauty and performance stability. Good flame retardancy: Polycarbonate is a B1 grade flame retardant material (according to GB 8624-2012 standard). It is self-extinguishing away from fire, and it is not easy to promote the spread of fire, providing a certain fire safety guarantee for commercial places. Sound insulation and heat insulation effect: Although it is not the main sound insulation and heat insulation material, crystal rolling shutter doors can also block noise transmission to a certain extent due to their airtightness, and reduce indoor and outdoor heat exchange, which helps to maintain the relative stability of the indoor environment. II. Structural design and driving method

The overall structure of a crystal rolling shutter door is usually composed of the following parts:

Door sheet (curtain sheet): that is, transparent polycarbonate sheet, the thickness of a single sheet is usually ranging from 3mm to 5mm, according to the needs and the size of the door body. The plates are connected in series through specially designed connectors. Connection structure: In order to enhance the overall strength and aesthetics of the door body, high-strength aluminum alloy profiles or stainless steel tubes are usually used as connecting ribs between the polycarbonate door sheets. These metal components not only play a role in connection and reinforcement, but also complement the transparent door sheet with their own luster and texture, enhancing the overall sense of fashion. Guide rail and bottom beam: The guide rails on both sides ensure the smooth operation of the door body up and down, and the bottom beam increases the counterweight and sealing of the bottom of the door. These parts are usually also made of aluminum alloy or stainless steel to ensure durability and corrosion resistance. Reel and cover: When the door body is put away, it is wound on the top reel. Some high-end designs will also be equipped with a cover that is coordinated with the style of the door body to hide the reel and make the whole more beautiful and tidy. In terms of driving mode, crystal rolling shutter doors are similar to traditional rolling shutter doors. There are mainly the following:

Manual drive: It is suitable for crystal rolling shutter doors with smaller door openings and lighter weight. It can be opened and closed by human pulling, and the cost is low. Electric drive: This is the most common and convenient way. The door body is automatically lifted and lowered by driving the reel to rotate through the built-in tubular motor or external motor. It can be matched with a variety of control methods such as wall button switch and remote control. The electric system usually has a stop/rebound function in case of resistance, which increases safety. Chain hoist drive (spare): For large electric crystal rolling shutter doors, a manual chain hoist is usually equipped as an emergency device, so that the door can be opened or closed in the event of a power outage or motor failure. III. Wide range of application fields and value reflects

With its unique transparent display effect, reliable security protection and fashionable and modern appearance, crystal rolling shutter doors have been widely used in the following fields:

Commercial retail stores: such as clothing stores, jewelry stores, cosmetics stores, electronic product stores, automotive 4S store exhibition halls, etc. Crystal doors not only ensure night safety, but more importantly, its "perspective" characteristics allow goods to still attract passers-by after closing the store, invisibly prolonging the display time and stimulating consumer desire. Shopping centers and large shopping malls: various stores in the mall are partitioned, atrium passages, etc. The use of crystal rolling shutter doors can not only divide the area, but also maintain the transparency and visual connection of the overall space, and enhance the overall modern and high-end atmosphere of the mall. Banking, telecommunications business hall and other service windows: during non-business hours, crystal doors can provide security protection, while its transparency also reduces the sense of closure and oppression in the space. High-end residential and villa garage: Some owners who pursue personalization and modernity will also choose crystal rolling shutter doors as garage doors, which can not only display their cars, but also add a unique landscape to the residence. Other public or commercial spaces: such as exhibition booths, airport shops, subway shops, etc., where safety, display and aesthetics need to be taken into account, crystal rolling shutter doors are the ideal choice. IV. Purchase and Maintenance Suggestions

When purchasing a crystal rolling shutter door, the following points should be paid attention to:

Sheet Quality: Choose a polycarbonate plate with a well-known brand, high light transmittance, uniform UV coating, and no obvious impurities and scratches. Connectors and Hardware: The connected aluminum alloy or stainless steel profiles should have sufficient thickness and strength. The quality of the hardware (such as guide rails, bearings, etc.) also directly affects the service life and smoothness. Motor Brand and Performance: If you choose an electric door, you should choose a motor brand with good reputation, stable operation and low noise, and pay attention to its warranty policy. Installation Process: Professional installation is the key to ensure the normal operation and best performance of the crystal rolling shutter door. An experienced installation team should be selected. Daily maintenance is relatively simple:

Regularly use a soft cloth and neutral cleaner to wipe the surface of the door panel to keep it clean and translucent. Avoid using cleaning agents with strong acid and alkali properties or rough fabrics to avoid damaging the surface of the board. Regularly check whether there is any debris in the guide rail and lubricate it moderately. Check whether the motor runs smoothly and has no abnormal noise. Avoid hard objects hitting or scratching the door panel.